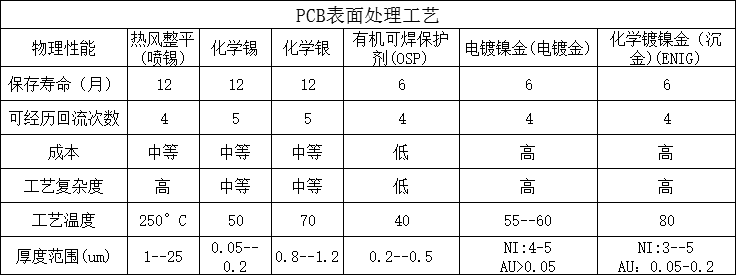

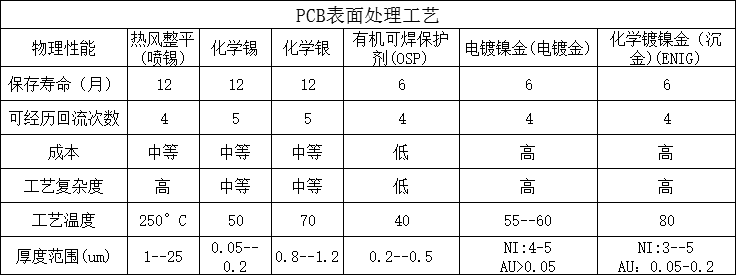

Considering the difference in process and storage conditions of PCB products, the PCB should be used in time after unpacking (recommended within 24 hours). It is recommended to pre-dry before use, especially the PI substrate in flexible PCB. If patch welding is required, a pre-drying process is required.

For chemical tin or silver impregnated products, it is recommended to use up within 12 hours after unpacking, otherwise it must be repackaged.

If the shelf life exceeds the effective shelf life, the user can try after drying: if necessary, will test some performance again and will still be available after passing the test.

To avoid the risk of moisture, the PCB must be baked for 2 hours and 150 degrees before being placed on the machine for more than 3 months.

PCB shelf life and storage environment:

A. Good storage conditions: refers to the indoor environment with temperature control and non-corrosive gases, the temperature is below 25 degrees, and the relative humidity is less than 65%.

B. General storage conditions: refers to indoor environmental conditions, the temperature is not higher than 35 degrees, the relative humidity is not more than 75%, and there is no corrosive gas.

CASE

MORE >>

CASE

MORE >>

Hot News

MORE >>

Hot News

MORE >>